Using one of the most advanced neoprene’s on the market, Yamamoto 39, Lennon Racewear incorporates the materials, design & functionality to make your sailing warm, comfortable and above all DRY.

In order to create a DRY SYSTEM, we have chosen specific materials that can be used in a unique design, created in the UK, for cold water sailing.

Yamamoto 39 and 45

- 99.7% Calcium Carbonate NOT petroleum based rubber

- 6 times the stretch memory of other wetsuits

- 30% less water absorption compared with other rubbers

What does this mean?

It’s as environmentally friendly as any neoprene can be.

It lasts for longer – after 6 months you will still have the same stretch and comfort as the first day you bought it unless many of its competitors.

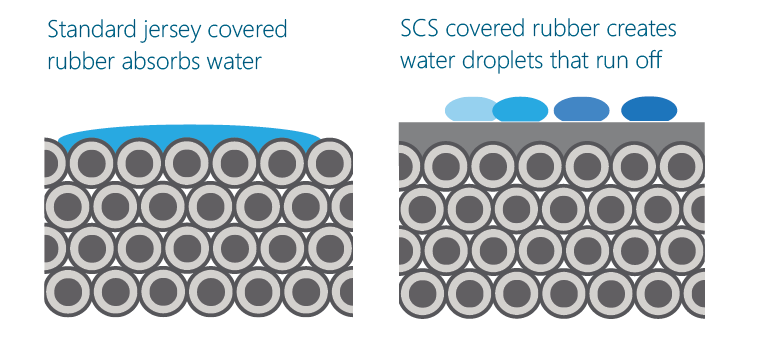

It absorbs less water than most other neoprene’s, which means it dries quicker but also keeps you much warmer as the wind chill factor is very low.

We use SCS (Super Composite Skin) single lined neoprene on key panels for heat retention.

100% waterproof seams:

Lennon Racewear’s DRY SYSTEM relies on our materials and manufacture being waterproof. We have told you about Yamamoto 39 /45 now let us tell you how we put the suits together.

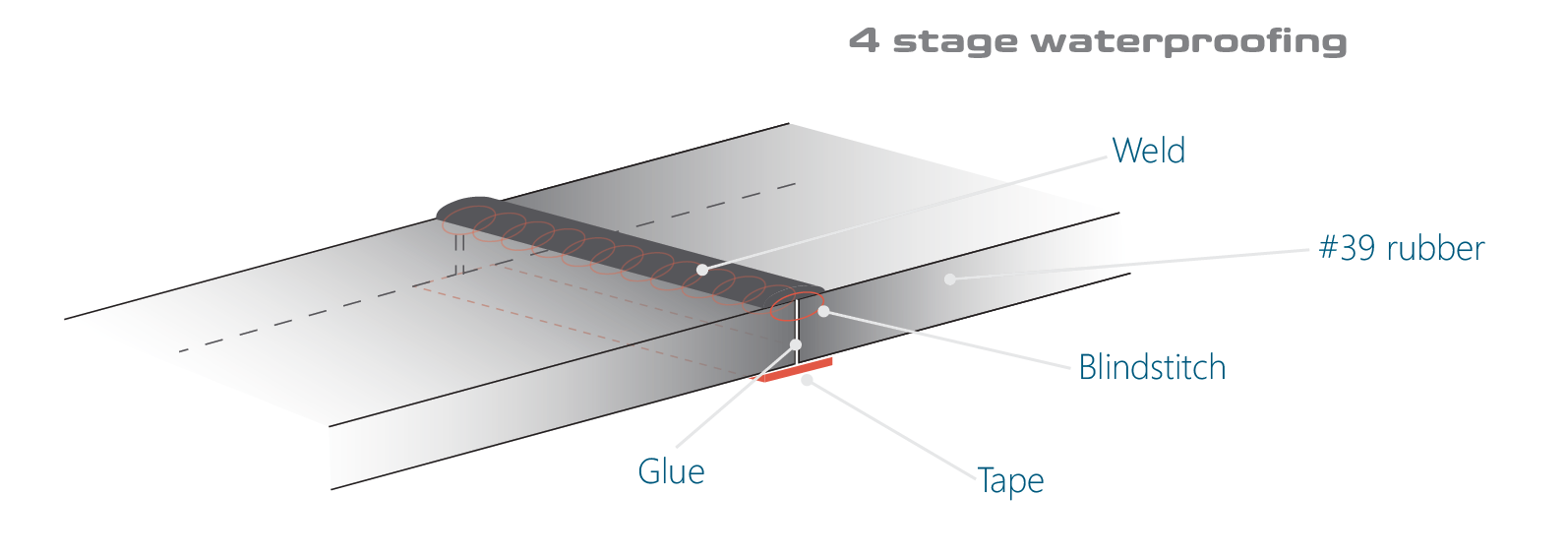

We are probably the only manufacture in the sailing world that uses a 3 & 4 stage waterproofing system.

All seams are GLUED, BLINDSTITCHED, TAPED and some are also WELDED

How does this make a DRY SYSTEM?

The final piece of the jigsaw is the design of the suit and the material used to seal it…

We design our suits to seal together on the waist between the top and long john. We then use the same technology on the wrist and ankle seals. This is a coating called SCS – Super Composite Skin. It’s a unique material developed specifically for top-flight international athletic competition featuring a specially processed coating applied over the patented closed-cell neoprene rubber.